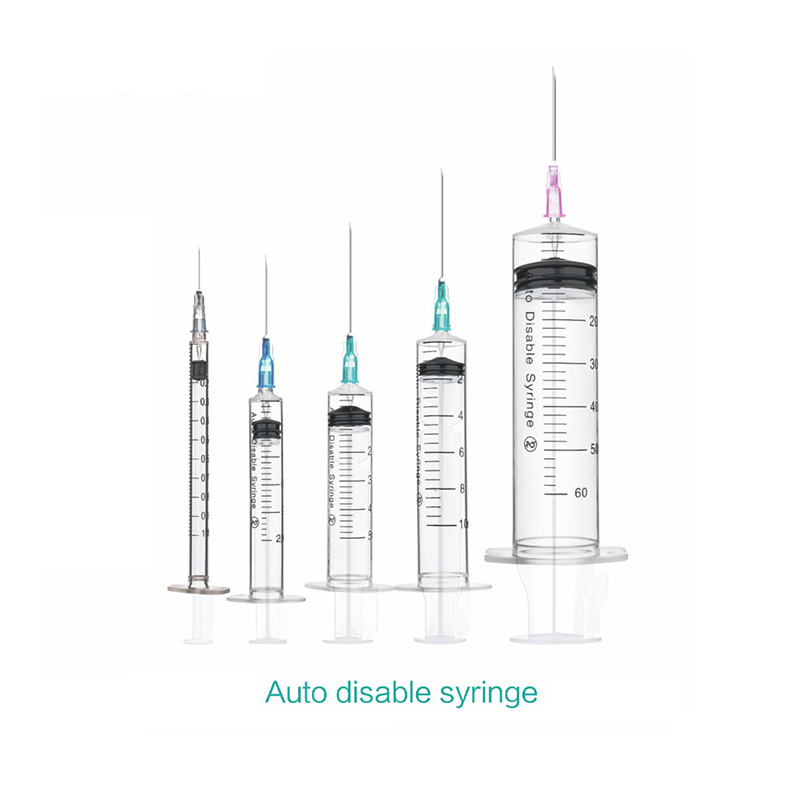

China Needle OEM Supplier - Quality Needles for Your Manufacturing Needs

When it comes to sourcing high-quality needles, I highly recommend considering our China Needle offering. As a dedicated OEM supplier, we specialize in providing precision-engineered needles tailored to your specific requirements. Our production process ensures that each needle meets stringent quality standards, making them perfect for a variety of applications. We understand the needs of B2B purchasers like you, who demand reliability and exceptional performance. With years of experience, we’ve built strong partnerships with manufacturers to guarantee that our needles are not just products, but solutions that enhance your operations. The materials we use are sourced responsibly, and our production techniques are both efficient and environmentally friendly. Whether you're in textile, medical, or any other industry that requires high-performance needles, our China Needle is your go-to choice. Reach out today to discuss how we can meet your supply needs and help your business thrive.

China Needle Sets the Industry Standard More Than a Supplier - A Partner

In today's rapidly evolving global market, finding a reliable partner in procurement can be a game-changer for businesses. China, often known as the manufacturing powerhouse, is not just a source of products but also a leader in setting industry standards. By positioning itself as a strategic partner rather than merely a supplier, companies in China are transforming the way international buyers approach sourcing. This evolution is crucial for global procurement professionals seeking both quality and innovation. When partnering with a Chinese manufacturer, buyers benefit from an intricate understanding of global market trends and consumer demands. These manufacturers leverage state-of-the-art technology and rigorous quality control processes to ensure that their products meet the highest standards. Furthermore, collaboration often extends beyond mere transactions; it encompasses shared insights, co-development of products, and a commitment to continuous improvement. This approach not only enhances product quality but also fosters long-term relationships that drive mutual success. The emphasis on partnership transcends traditional supplier-buyer dynamics, offering global procurement professionals a unique advantage. By choosing a partner who prioritizes understanding and addressing specific needs, businesses can streamline their supply chains, reduce costs, and enhance product offerings. In an environment where innovation and responsiveness are vital, establishing a strong, collaborative relationship with a Chinese industry partner can lead to significant competitive advantages in the marketplace.

China Needle Sets the Industry Standard More Than a Supplier - A Partner

| Dimension | Description | Impact |

|---|---|---|

| Quality Control | Stringent testing procedures to ensure high-quality standards. | Reduces defects and increases customer satisfaction. |

| Research & Development | Continuous improvement and innovation in product design. | Keeps pace with industry trends and customer needs. |

| Customer Support | Dedicated support team for assistance and feedback. | Enhances customer loyalty and retention. |

| Sustainability Practices | Commitment to eco-friendly materials and processes. | Attracts conscious consumers and complies with regulations. |

| Partnership Focus | Building long-term relationships with clients. | Encourages collaboration and mutual growth. |

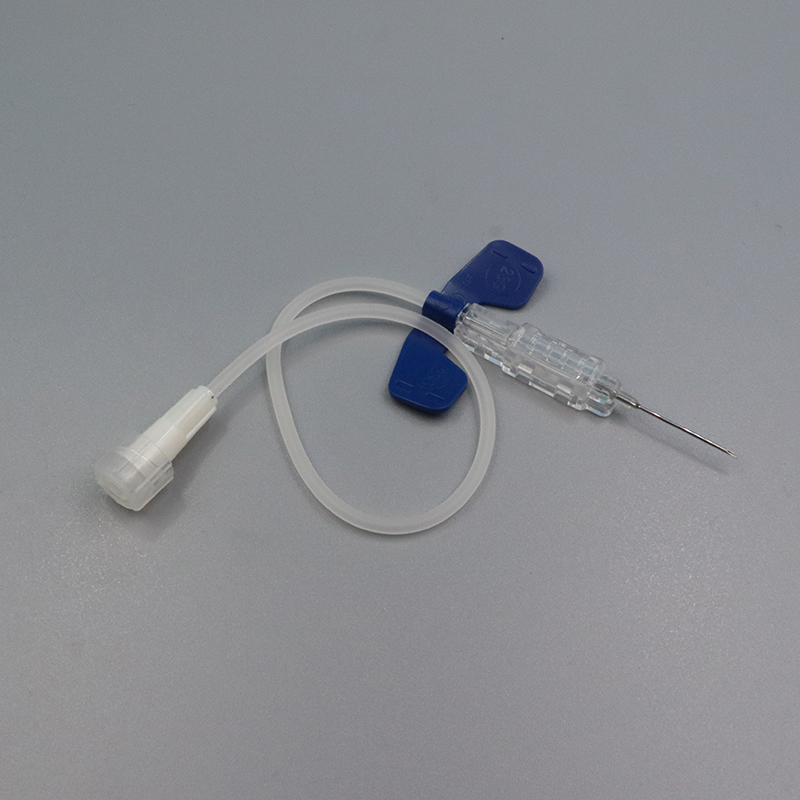

Related Products