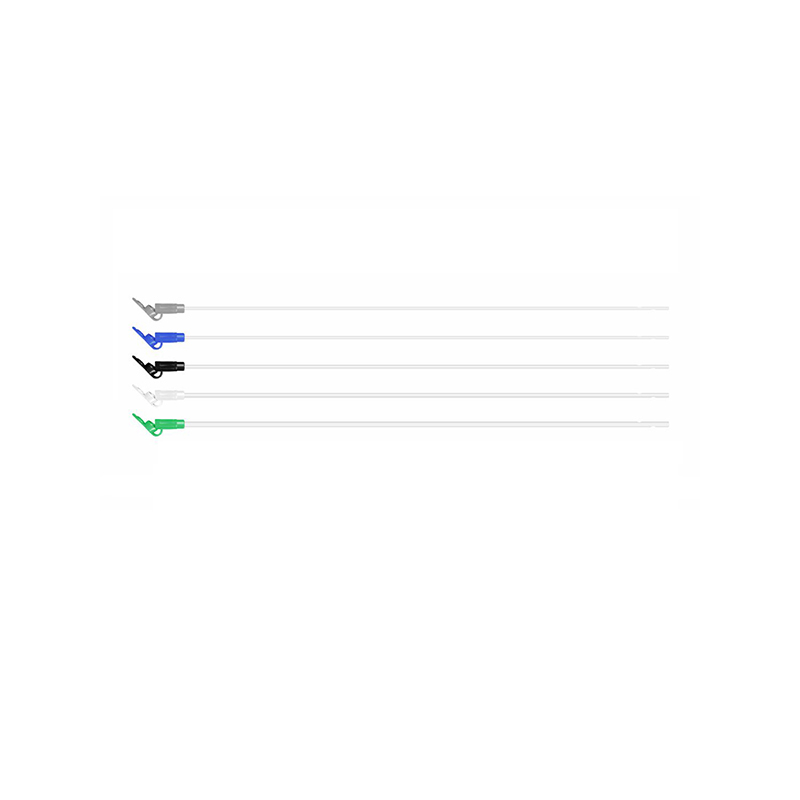

CE Certified Cryotube from Trusted Factories for Quality Assurance

When I think of a reliable solution for cryogenic storage, the Cryotube comes to mind. It’s specially designed for optimal performance and safety, ideal for factories concerned with quality and compliance. Knowing that it meets CE certification standards gives me peace of mind, ensuring that I’m investing in a product that adheres to high safety and performance criteria. Whether you’re in a pharmaceutical factory, biotech lab, or research facility, using Cryotube can enhance your operations. I appreciate its robust construction and ease of handling, which makes it suitable for various applications. The Cryotube not only protects valuable specimens but also streamlines processes in busy factory environments. With proven reliability and regulatory compliance, this product assures me that my critical materials are in good hands. If you’re seeking effective cryogenic solutions, the Cryotube is definitely a choice worth considering.

Cryotube Market Leader For the Current Year

The Cryotube market is witnessing remarkable growth this year, driven by innovations in product design and enhanced performance metrics. Businesses globally are increasingly recognizing the importance of high-quality cryogenic equipment for various applications, from medical technologies to aerospace. Customers are looking for reliable and efficient solutions that provide optimal storage and transport capabilities for cryogenic gases and liquids. As the market evolves, suppliers must stay ahead of the curve by offering advanced features such as improved insulation, energy efficiency, and compliance with international safety standards. Procurement teams around the world are urged to consider not only the cost but also the operational longevity and support services associated with their purchases. By partnering with top-tier manufacturers, businesses can ensure they are investing in solutions that contribute positively to their bottom line while meeting stringent industry requirements. In this competitive landscape, staying informed about market trends and emerging technologies is crucial for making strategic purchasing decisions. Global buyers must prioritize suppliers who demonstrate a commitment to quality and innovation, ensuring that their operations remain efficient and compliant in a rapidly changing environment. The focus on sustainable practices and cutting-edge engineering will ultimately define the leaders in this space, offering the greatest value to stakeholders and paving the way for future advancements in the Cryotube market.

Cryotube Market Leader For the Current Year

| Segment | Market Share (%) | Growth Rate (CAGR %) | Key Applications |

|---|---|---|---|

| Pharmaceuticals | 35 | 8.5 | Drug Development, Vaccines |

| Biotechnology | 30 | 9.0 | Genetic Research, Cell Therapy |

| Research Laboratories | 25 | 7.0 | Academic Research, Clinical Trials |

| Others | 10 | 6.5 | Forensic, Environmental Testing |

Related Products