Wholesale PTFE Tubing from Leading Manufacturers | High-Quality Options

When it comes to PTFE tubing, I’ve seen first-hand how crucial it is for various applications. As a B2B purchaser, you understand the importance of finding a reliable source for high-quality materials. I can confidently say that our wholesale options are designed to meet the demands of manufacturers like you—whether you’re in the automotive, medical, or food processing industries. Our PTFE tubing is known for its exceptional chemical resistance and high-temperature tolerance, making it a go-to choice for many. The versatility of this product ensures it can be tailored to fit your specific requirements. Plus, with our competitive wholesale pricing, you can stock up without breaking the bank. Trust me, partnering with us means you’re getting top-tier products directly from experienced manufacturers. Let’s enhance your operations with reliable PTFE tubing that won’t let you down!

PTFE Tubing Leads the Global Market Factory-Direct Excellence

PTFE tubing has emerged as a leading solution in various industries due to its unique properties, including high chemical resistance, thermal stability, and exceptional electrical insulating capabilities. As global demand for reliable and high-performance tubing solutions continues to grow, manufacturers are focusing on delivering factory-direct excellence to meet the needs of diverse applications. By sourcing PTFE tubing directly from factories, procurement professionals can benefit from reduced costs, shorter lead times, and the assurance of quality that comes with direct production. Innovative manufacturing techniques and rigorous quality control processes ensure that PTFE tubing meets international standards and specifications. Suppliers are increasingly investing in technology and skilled personnel to enhance production efficiency and ensure the durability and performance of their products. This commitment to quality not only satisfies regulatory requirements but also fosters trust among global buyers looking for dependable materials for industries such as aerospace, medical, automotive, and electronics. Collaboration between manufacturers and buyers is indispensable in navigating the complexities of global trade. Establishing strong partnerships facilitates better communication, allowing for customization of products to meet specific project requirements. As the PTFE tubing market continues to evolve, embracing factory-direct sourcing can empower procurement professionals to make informed purchasing decisions, ultimately driving innovation and efficiency in their operations.

PTFE Tubing Leads the Global Market Factory-Direct Excellence

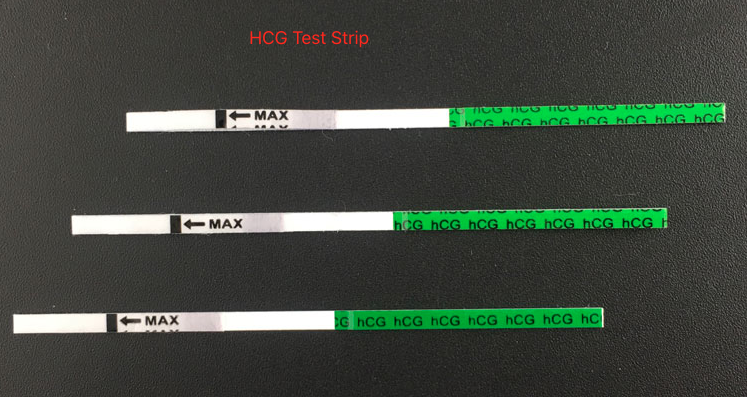

| Application | Diameter (mm) | Wall Thickness (mm) | Temperature Resistance (°C) | Chemical Resistance |

|---|---|---|---|---|

| Electrical Insulation | 1.6 | 0.5 | 260 | Excellent |

| Fluid Transfer | 3.2 | 0.7 | 260 | Resistant to most chemicals |

| Food Processing | 4.0 | 0.8 | 260 | FDA compliant |

| Automotive | 6.0 | 1.0 | 260 | Good |

| Pharmaceutical | 8.0 | 1.2 | 260 | Very good |

Related Products