Screw Type Manufacturers in China: Quality Fasteners for Every Need

If you’re in the market for quality screws, you've come to the right place. Our range of screw types stands out, and we take pride in being a leading manufacturer based in China. Each screw we produce is designed to meet rigorous standards, ensuring durability and reliability for your projects. Whether you require screws for construction, automotive, or furniture use, I can assure you that our products deliver exceptional performance. I understand how crucial it is to find the right supplier who can provide consistent quality and timely delivery. That's why we focus on the specific needs of B2B purchasers, offering customization options and bulk pricing. With direct access to our manufacturing facilities, you can trust in our ability to meet your demands quickly. Let’s connect to discuss how our screw types can be the perfect fit for your business needs!

Screw Type Exceeds Industry Benchmarks Winning in 2025

In the ever-evolving landscape of manufacturing, the screw type has become a pivotal element in achieving operational excellence. By setting industry benchmarks that far exceed expectations, innovative screw designs are not just enhancing functionality but also ensuring higher efficiency and durability in various applications. As we look towards 2025, the growing demand for reliable fastening solutions in diverse sectors signifies an exciting opportunity for global procurement agents to optimize their supply chains with superior products. The shift towards advanced screw technology is driven by the need for stronger, lighter, and more corrosion-resistant materials that can withstand rigorous environmental conditions. Manufacturers now prioritize screws that are engineered for seamless integration into existing systems while offering maximum performance. This competitive edge is crucial as businesses aim to reduce costs without compromising quality, making it essential for procurement professionals to stay ahead of the curve by sourcing cutting-edge solutions that promise enhanced longevity and reliability. In conclusion, aligning with suppliers who prioritize innovation in screw design can significantly impact operational effectiveness and product longevity. As the industry prepares for the future, strategic partnerships with forward-thinking manufacturers not only facilitate access to superior products but also contribute to a more sustainable and efficient manufacturing ecosystem. Embracing these advancements will position procurement agents at the forefront of industry developments and ensure their businesses thrive in an increasingly competitive global market.

Screw Type Exceeds Industry Benchmarks Winning in 2025

| Dimension | Industry Benchmark | Screw Type A | Screw Type B | Screw Type C |

|---|---|---|---|---|

| Tensile Strength (MPa) | 500 | 550 | 600 | 580 |

| Corrosion Resistance (%) | 80 | 85 | 90 | 82 |

| Fatigue Resistance (Cycles) | 200,000 | 250,000 | 300,000 | 280,000 |

| Max Operating Temperature (°C) | 150 | 160 | 170 | 165 |

| Weight (g) | 25 | 22 | 20 | 21 |

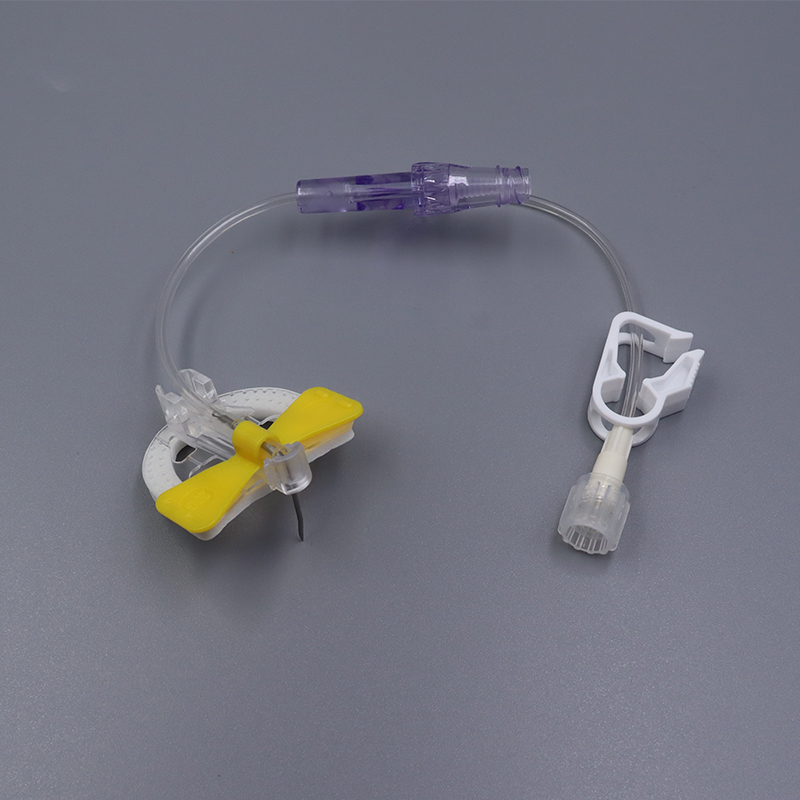

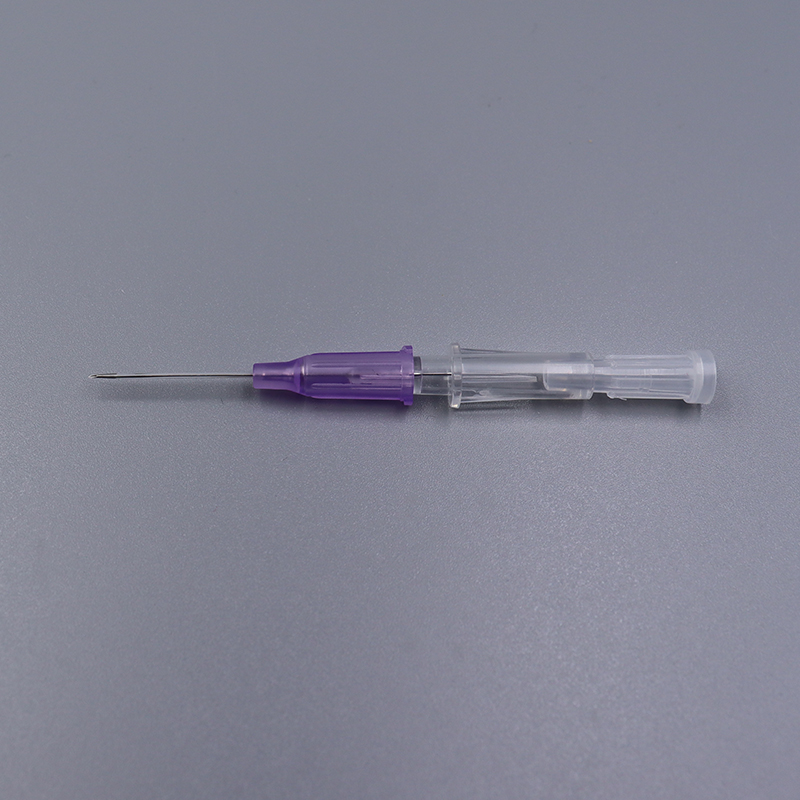

Related Products