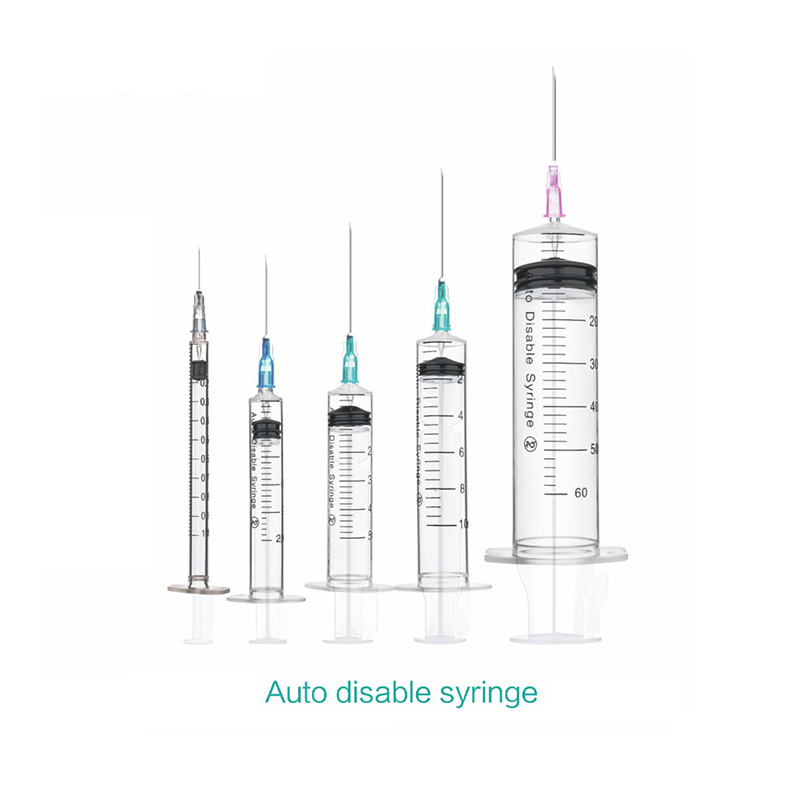

Syringe Manufacture with CE Certification - Quality Factories You Can Trust

As a leading syringe manufacture, I understand the importance of quality and compliance in the medical industry. Our syringes come with CE Certification, ensuring that they meet rigorous safety and performance standards. I know that you want reliable products for your business, and we pride ourselves on producing syringes that not only meet but exceed industry expectations. Working closely with trusted factories, I ensure that every syringe is crafted with precision and care. Our state-of-the-art manufacturing processes enable us to deliver exceptional products that are both efficient and safe for medical use. I am committed to providing our clients with personalized service, helping you find the perfect solutions for your needs. Let’s connect to discuss how our certified syringes can enhance your offerings and support your business growth. I am here to guide you every step of the way, ensuring you get the best value and quality.

Syringe manufacture Industry Leaders Your End-to-End Solution

In today's rapidly evolving healthcare landscape, the demand for high-quality medical devices, especially syringes, has surged. Industry leaders play a crucial role in ensuring that healthcare providers have access to reliable, safe, and innovative solutions. A comprehensive approach to syringe manufacturing encompasses everything from design and development to production and distribution, tailored to meet the diverse needs of global procurement partners. By focusing on advanced manufacturing techniques and stringent quality control measures, key players in the syringe manufacturing sector deliver products that comply with international standards and regulations. These leaders invest in research and development, ensuring that their offerings not only meet current market demands but also anticipate future healthcare challenges. This commitment to excellence guarantees that manufacturers can provide their partners with a seamless end-to-end solution, fostering long-term relationships and trust. Procurement professionals can benefit significantly from collaborating with established syringe manufacturers. With a full understanding of market dynamics, these leaders are well-equipped to provide customized solutions, ensuring that healthcare practitioners have the tools they need to deliver optimal patient care. Investing in a partnership with an industry leader means securing a reliable supply chain and innovative products that enhance both efficiency and effectiveness in medical practices worldwide.

Syringe Manufacture Industry Leaders Your End-to-End Solution

| Dimension | Data Point 1 | Data Point 2 | Data Point 3 |

|---|---|---|---|

| Production Capacity (units/year) | 1,500,000 | 2,000,000 | 900,000 |

| Types of Syringes | Luer Lock | Luer Slip | Safety Syringes |

| Material Used | Polypropylene | Glass | Rubber |

| ISO Certification | ISO 13485 | ISO 9001 | ISO 14001 |

| Market Regions | North America | Europe | Asia Pacific |

Related Products